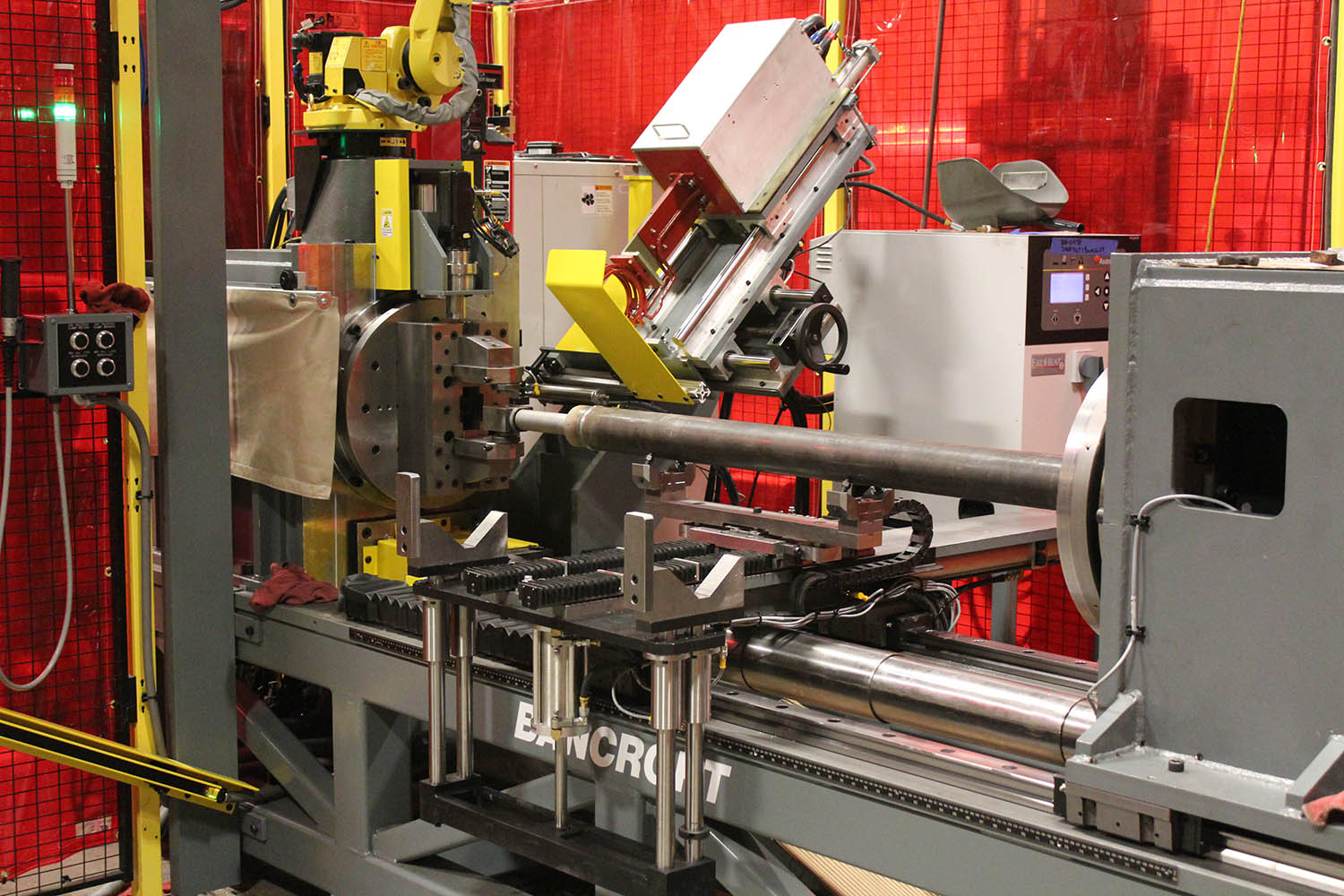

Welding, an integral element of metal fabrication, is both an art and science. At Bancroft Engineering, we understand that the integrity of any weld is also the integrity of its overall structure—whether automotive, aerospace or any other heavy industry— any imperfect welds may result in catastrophic failures that lead to catastrophic results. That is why in addition to providing state-of-the-art automated and semi-automated welding equipment we also build-in stress relieving solutions to mitigate against weld failure risks. Read on for more!

About Weld Stress Relieving

Stress relieving is an integral component of welding that often gets overlooked when deadlines and output requirements become overwhelming. Stress relieving involves relieving residual stresses caused by welding that accumulate in metal during the process; unmanaged residual stresses may lead to distortions, cracking, or structural failure in severe cases.

Stress relief lies not just within welding itself but must be managed before, during, and post welding for maximum effectiveness.

Automated Welding Equipment & Stress Relieving

Bancroft Engineering prides itself on offering welding solutions that seamlessly incorporate stress-relief techniques into their workflow, such as our Welda-Round family of rotary welders, with its precision and reliability, providing the ideal environment to incorporate stress-relieving techniques, especially with circular welds where potential stress concentration may exist.

Our automated welding systems, like the Welda-Long linear seam welders, are specially tailored to longitudinal welds. Their main purpose is to maintain uniformity and minimize stress buildup along long seams while supporting pre-heating and post-heating cycles that aid the stress relief process.

Stress management is also achieved through our semi-automated welding systems’ adaptability, such as our welding positioner lines, which are not only capable of accommodating various sizes and configurations but can easily enable operators to apply stress-relief techniques. Their precise control enables regulated cooling necessary for providing post-weld stress relief.

Credit : Source Post