Common problems in sub-arc welding can affect weld quality, penetration and overall performance.

Submerged arc welding (SAW) troubleshooting involves identifying and addressing issues that may arise during the welding process.

Firstly, what is Submerged-arc welding?

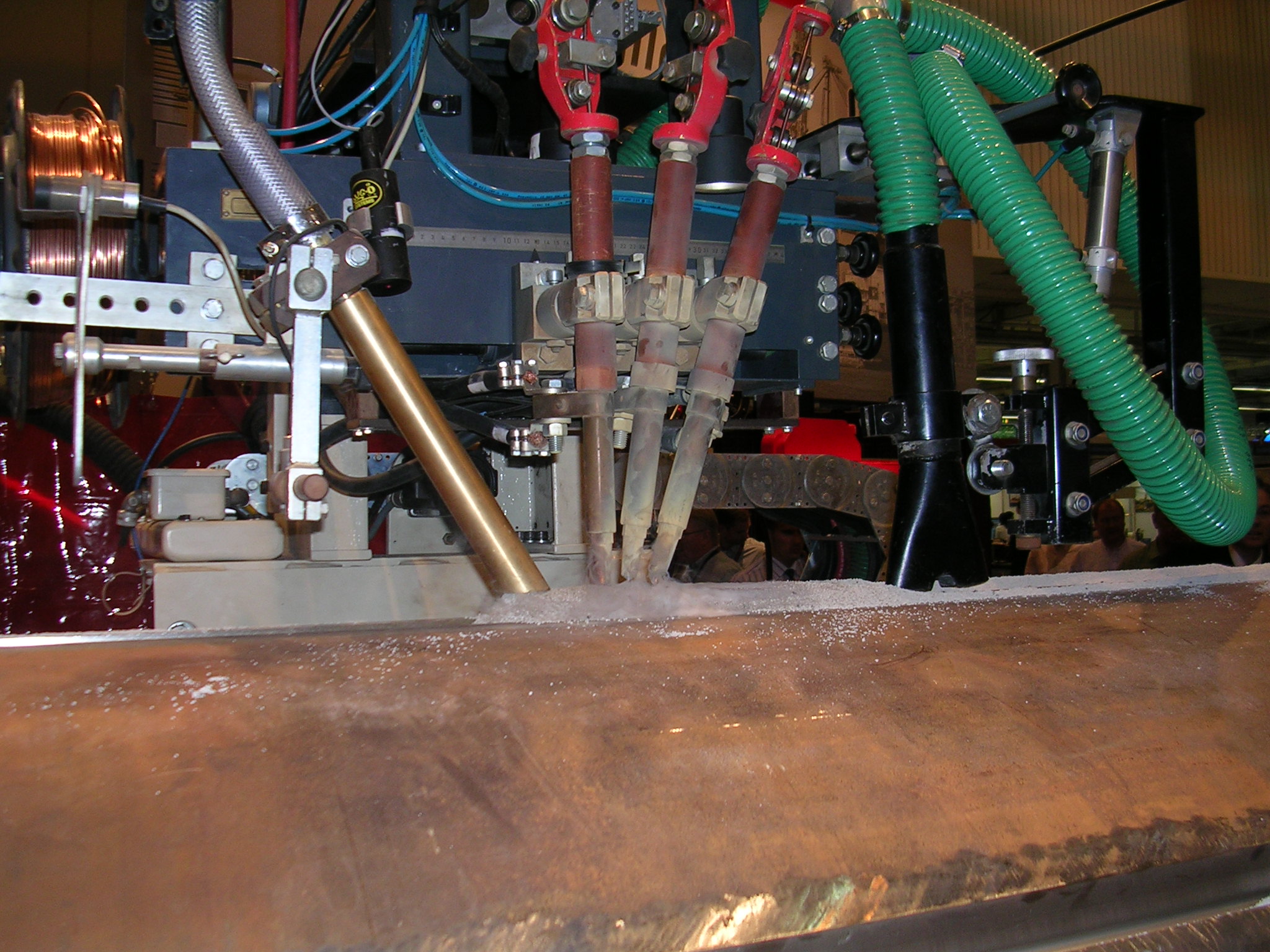

SAW is a common arc welding process that involves the formation of an arc between a continuously fed electrode and the workpiece. A blanket of powdered flux generates a protective gas shield and a slag (and may also be used to add alloying elements to the weld pool) which protects the weld zone. SubArc welding is typically used for thicker materials such as plate steel and pipe.

Used extensively in pressure vessel fabrication, pipe manufacturing, ship and barge building, railroad fabrication and the fabrication of structural members where long welds are required. SubArc welding. SAW is typically used to weld flat position, however horizontal position welding can also be achieved by using proper tooling and fixtures.

Here are some common troubleshooting tips for SAW:

1. Insufficient Penetration:

Possible Causes:

Low current or voltage settings.

Excessive travel speed.

Inadequate joint preparation.

Troubleshooting:

Increase current or voltage to achieve sufficient heat input.

Adjust travel speed to allow for proper penetration.

Ensure proper joint preparation, including bevel angle and root gap.

2. Excessive Penetration:

Possible Causes:

High current or voltage settings.

Slow travel speed.

Excessive joint preparation.

Troubleshooting:

Reduce current or voltage to control heat input.

Increase travel speed.

Adjust joint preparation to avoid excessive penetration.

3. Weld Bead Irregularities:

Possible Causes:

Uneven flux distribution.

Incorrect wire feed or arc voltage settings.

Poor wire alignment.

Troubleshooting:

Ensure proper flux distribution by checking the flux hopper and feed system.

Adjust wire feed and arc voltage settings for a stable arc.

Verify that the wire is properly aligned and centred.

4. Porosity in Weld Bead:

Possible Causes:

Contaminated flux.

Moisture in the flux.

Insufficient preheating.

Troubleshooting:

Use dry and uncontaminated flux.

Store flux in a dry environment to prevent moisture absorption.

Increase preheating if necessary, especially for thick materials.

5. Incomplete Fusion:

Possible Causes:

Insufficient heat input.

Inadequate flux coverage.

Poor joint fit-up.

Troubleshooting:

Increase current or voltage for better heat input.

Ensure proper flux coverage to protect the arc and molten pool.

Improve joint fit-up for better fusion.

6. Flux Inclusion in Weld Bead:

Possible Causes:

Improper flux application.

Flux contaminated with foreign materials.

Incorrect welding parameters.

Troubleshooting:

Ensure even and consistent flux application.

Use clean and uncontaminated flux.

Adjust welding parameters to prevent flux entrapment.

7. Arc Instabilities or Arc Blow:

Possible Causes:

Magnetic interference.

Incorrect electrode polarity.

Insufficient or excessive flux coverage.

Troubleshooting:

Address magnetic interference by repositioning the workpiece or using magnetic field controls.

Verify and use the correct electrode polarity.

Adjust flux coverage to stabilize the arc.

8. Uneven Weld Bead:

Possible Causes:

Uneven joint fit-up.

Inconsistent wire feed.

Irregular flux distribution.

Troubleshooting:

Improve joint fit-up for uniform welding.

Ensure consistent wire feed and adjust as needed.

Verify and correct flux distribution for a uniform weld.

It’s important to note that troubleshooting in submerged arc welding may require a systematic approach and collaboration with experienced welding operators.

Regular maintenance of equipment, proper flux handling, and adherence to recommended welding parameters contribute to minimizing issues during the welding process.

Additionally, referring to the manufacturer’s guidelines for specific equipment and flux recommendations is essential for successful troubleshooting.

If you are looking to upgrade or buy subarc welding equipment, we can offer advice and a choice of equipment like we did for this UK heavy fabrication company. Learn more in the Case Study

Responsive Engineering quoted “The ESAB submerged arc welding system attached to the Bode column and boom manipulator, has allowed us to carry out high deposition rate welding during the latter part of jetty construction sections, increasing our skill levels in the process whilst rapidly recouping its initial cost,”

We recommend The Welding Institute as a great source of information for any welding process – What is SAW is explained in full here

Credit : Source Post